FAQ

ArtFORMS® 101

What are ArtFORMS® cast-in-place Architectural Concrete Bases?

ArtFORMS® cast-in-place Architectural Concrete Bases are an original, world-first, proven concept for affordable, attractive, quality cast-in-place architectural concrete support bases for a broad range of applications.

Applications include – site lighting pole bases, floodlight bases, lighting bollard bases, protective bollards, flagpole bases, column bases, sign post bases, gazebo/pavilion/pergola/trellis post bases, fence/gate post bases, deck post bases, porch post bases, driveway lamp post bases, numerous other base applications.

How are ArtFORMS® bases produced?

ArtFORMS® bases are cast-in-place on the jobsite by the property owner’s construction contractor with the purchase and use of world-first-original concept ArtFORMS® Concrete Forms – recyclable & biodegradable. ArtFORMS® are a versatile, easy-to-use, convenient, cost-effective building product.

What are the alternatives to ArtFORMS® bases?

The only known commercial alternative to ArtFORMS® bases are the all-too-familiar, low-quality, round (cylindrical), ‘plain Jane’, spiral seam-marked tube-formed concrete bases.

Tube-formed bases are cast on the jobsite by the pouring of ready-mix concrete into single-use, disposable, ‘cardboard’ tube forms available in various diameters & standard lengths.

Tube forms are generically known as ‘fiber forms’. They are commercially available under various brand names.

*** Tube-formed bases are characteristically crude, unsightly, low-quality, conservatively-oversized & costly! ***

What are the key advantages of ArtFORMS® bases for site lighting pole bases & other applications?

ArtFORMS® bases, complete with popular, optional Reflective Color Accent Bands, are an impressive architectural feature which enhances the appearance of the exterior building site or streetscape.

ArtFORMS® bases are affordable, attractive, easy-to-install. They are available in a wide selection of architectural styles & sizes – both contemporary & traditional.

ArtFORMS® bases are not ‘fancy’. Rather, they present a progressive, functional, clean, look of quality to any setting where they are installed.

ArtFORMS® bases for site lighting poles in parking lots enhance traffic safety when fitted out with high-visibility (daytime/nightime), optional Reflective Color Accent Bands (not applicable to all base styles).

Used ArtFORMS® Concrete Forms material is environmentally friendly. It can be recycled & made into other products. It is inert & can be conveniently used as clean site fill on jobsites, where applicable. It is biodegradable in commercial landfill sites.

How do the costs of ArtFORMS® bases compare to tube-formed bases?

Typically, the installed cost of ArtFORMS® architectural concrete bases is about the same as ‘plain-Jane’ tube-formed bases.

In the case of site lighting poles bases, for example, ArtFORMS® bases are cost-effectively engineered-to-size to suit the selected lighting pole heights, per ArtFORMS® Detail Dwgs.

By comparison, tube-formed bases are typically conservatively-oversized & costly.

Oversizing is particularly common in the case of bases for low & mid-height poles (up to 35’ (10.7m) high). In general, this is the result of Specifiers habitually taking the conservative & convenient one-large-size-concrete-base-fits-all-lighting-poles approach.

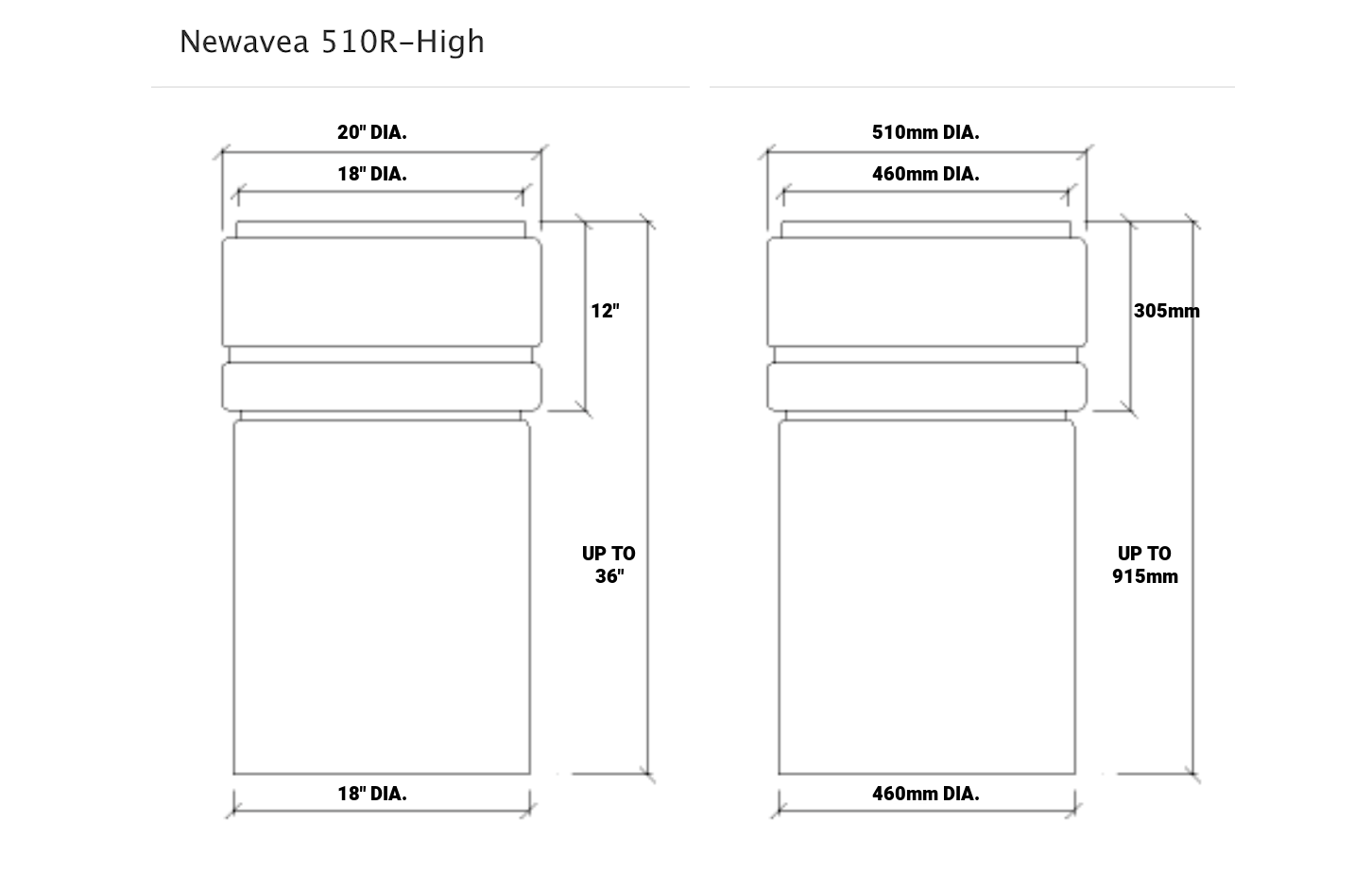

For example, take the common case of a 24” (610mm), 30” (760mm) or even up to 36” (915mm) diameter….. tube-formed base for say, a 20’ (6.1m) high lighting pole. A smaller, more visually in scale, less costly (less concrete, faster installation) Newavea 510R-High style ArtFORMS® base, engineered per our related Detail Dwg (Installation), is structurally adequate for poles up to 35’ (10.7m) high, for a typical installation in competent soils conditions.

The ArtFORMS® base is also a much higher-quality, far more attractive base than the typical tube-formed base.

In the case of installed costs for a same size lighting pole base comparison between typical tube-formed bases & ArtFORMS® bases, at 2′ (610mm) diameter x 3′ (915mm) high for example, there is a typical added installed cost for the ArtFORMS® base of about $40 to $50. Given the expected 40-50 year service life of the base, this is a small added investment for a long-lasting, noticeable, quality architectural feature versus an unsightly, low-quality base that detracts from the look & quality of the facility.

Relative to the cost of the total project, the small added cost of the higher-quality ArtFORMS® base asset is insignificant.

Prices for recyclable & biodegradable ArtFORMS® Concrete Forms start at $45.

How many styles / sizes of ArtFORMS® bases are available?

Presently, ArtFORMS® bases are available in 13 styles/size combinations, plus 1 style/any desired size.

ArtFORMS® Concrete Forms

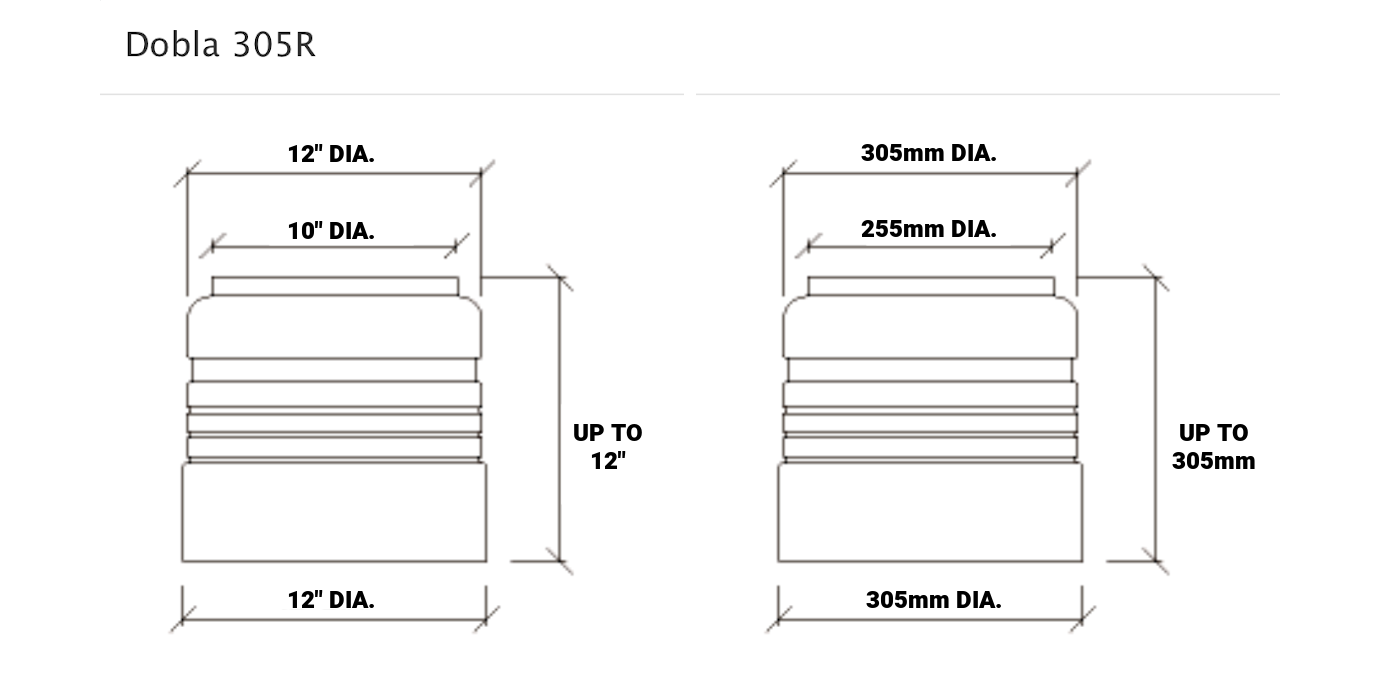

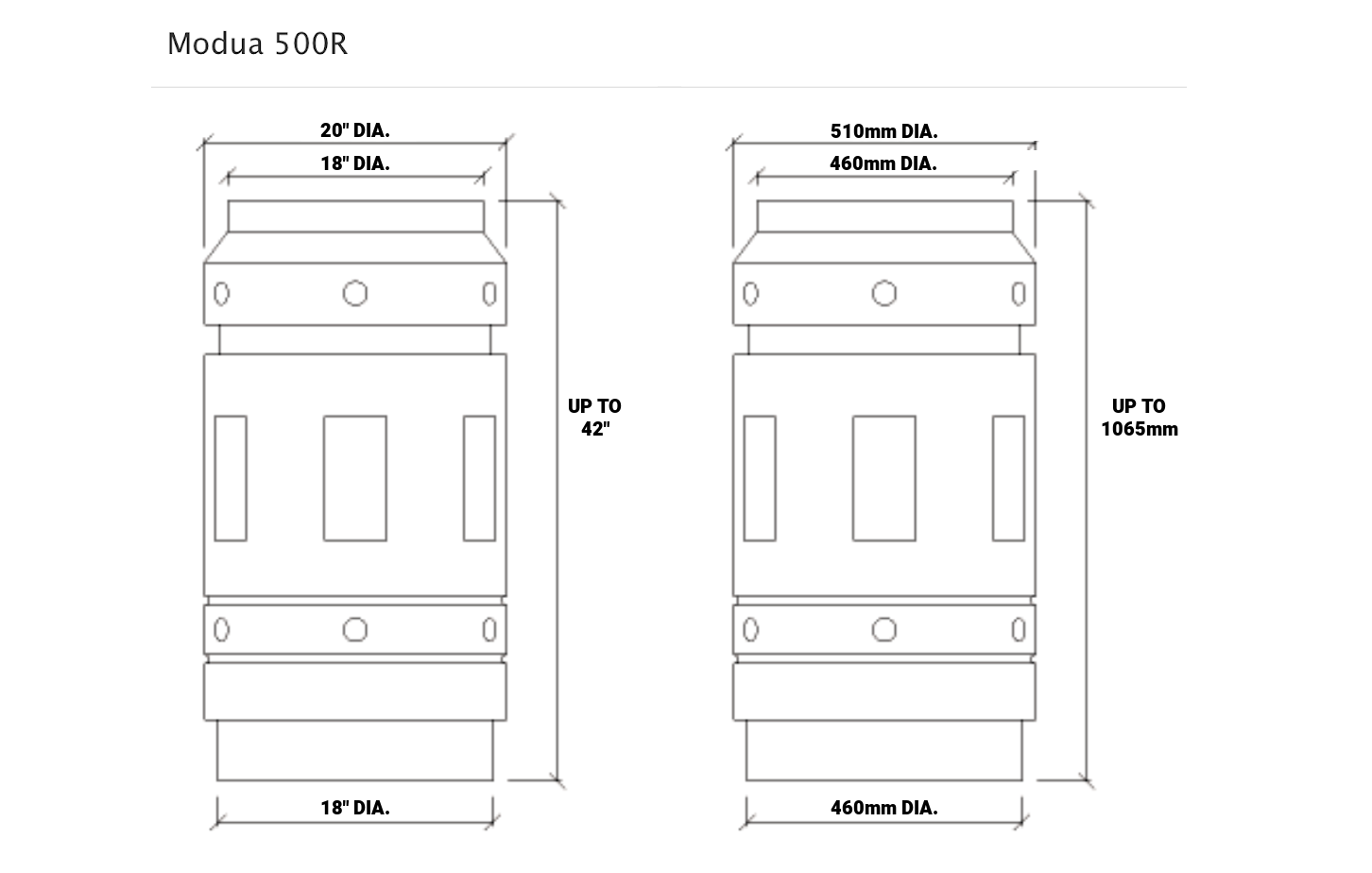

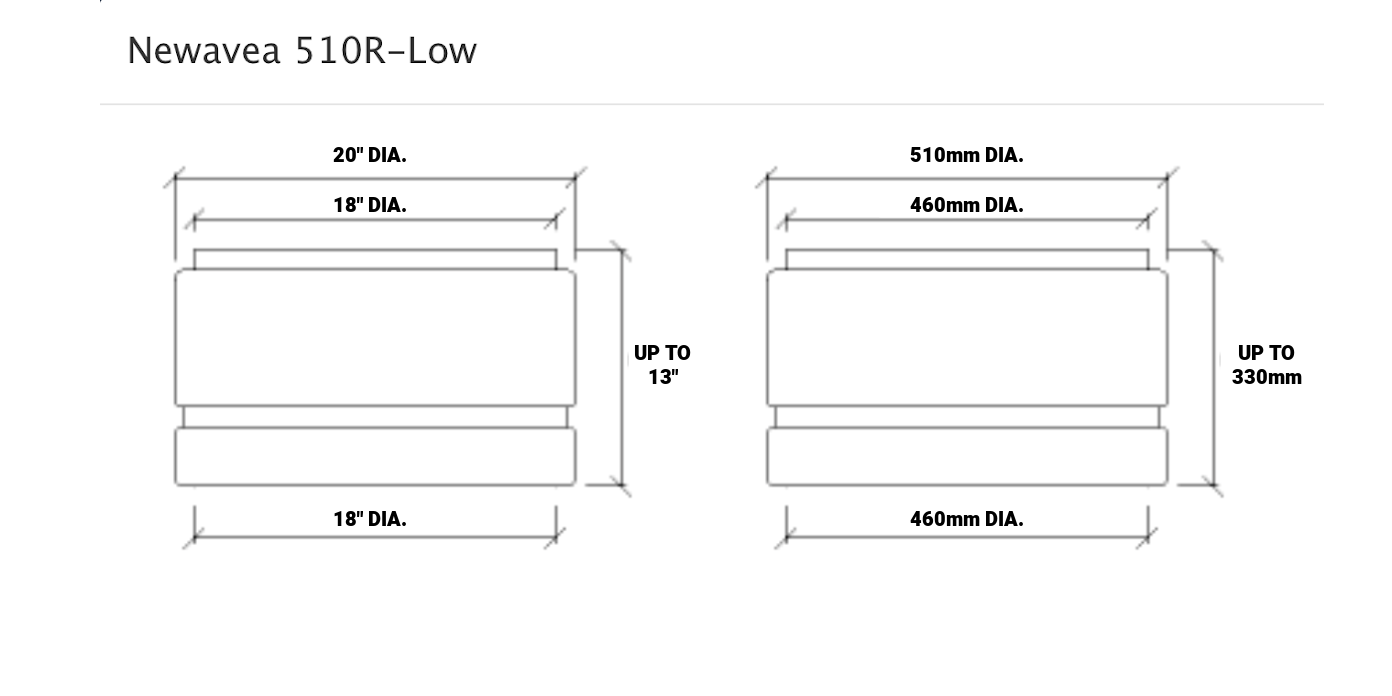

5 stock contemporary base styles (Kellamy, Newavea-High, Newavea-Low, Modua, Dobla) are offered in 1 size each. Sizes range from 24” (610mm) Diam. x 36” (915mm) H to 12” (305mm) Diam. x 12” H.

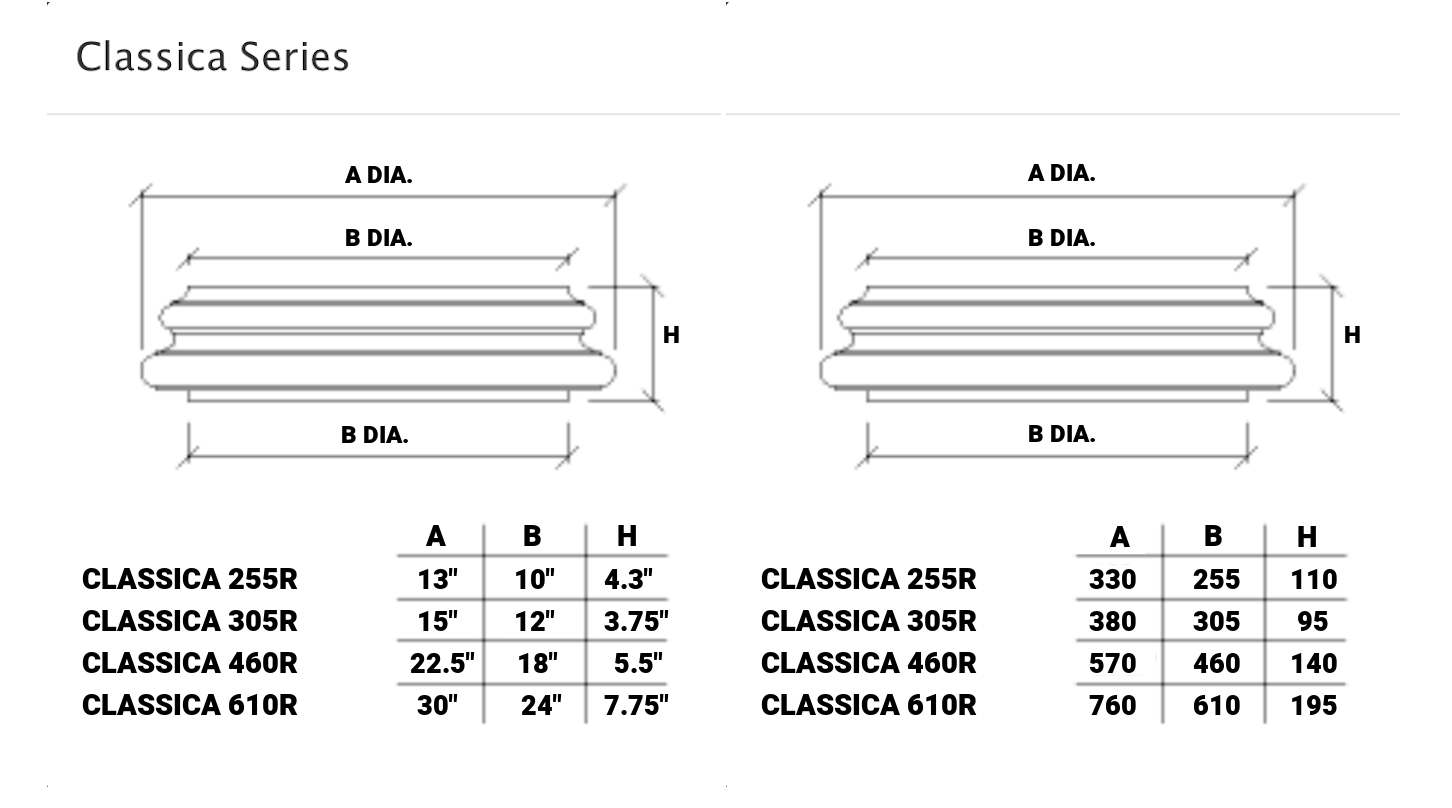

1 stock traditional base style (low-profile Classica series) 0mm) Diam.(top of conc.) x 5” (125mm) H.

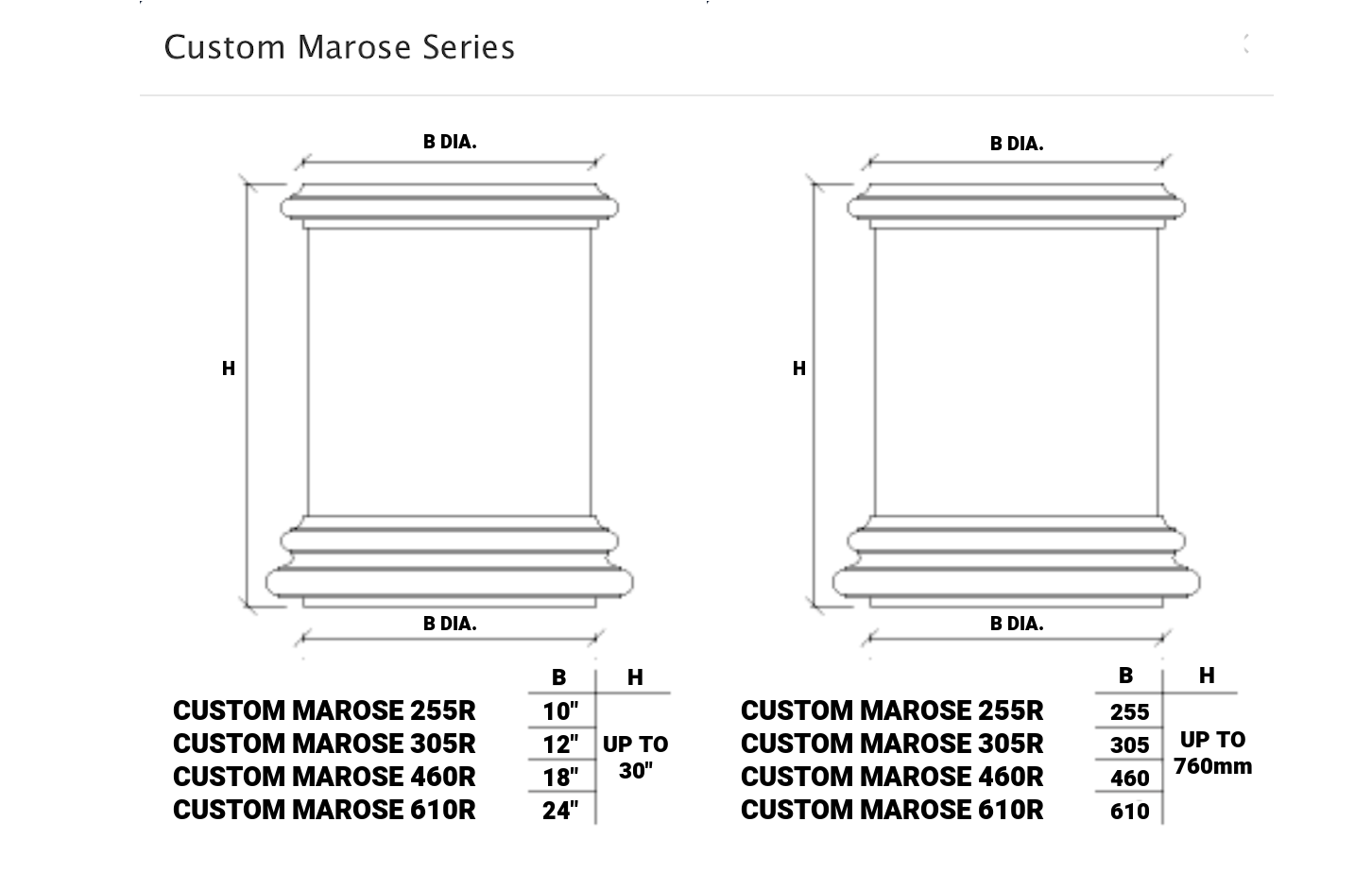

1 custom traditional base style (raised Marose series) is offered in 4 sizes. Sizes range from 24” (610mm) Diam. (top of conc.) x 30” (760mm) H (max) to 10” (250mm) Diam. (top of conc.) x 30” (760mm) H (max). (Base heights can be varied to suit customer requirements, up to maximum 30” (760mm) H)

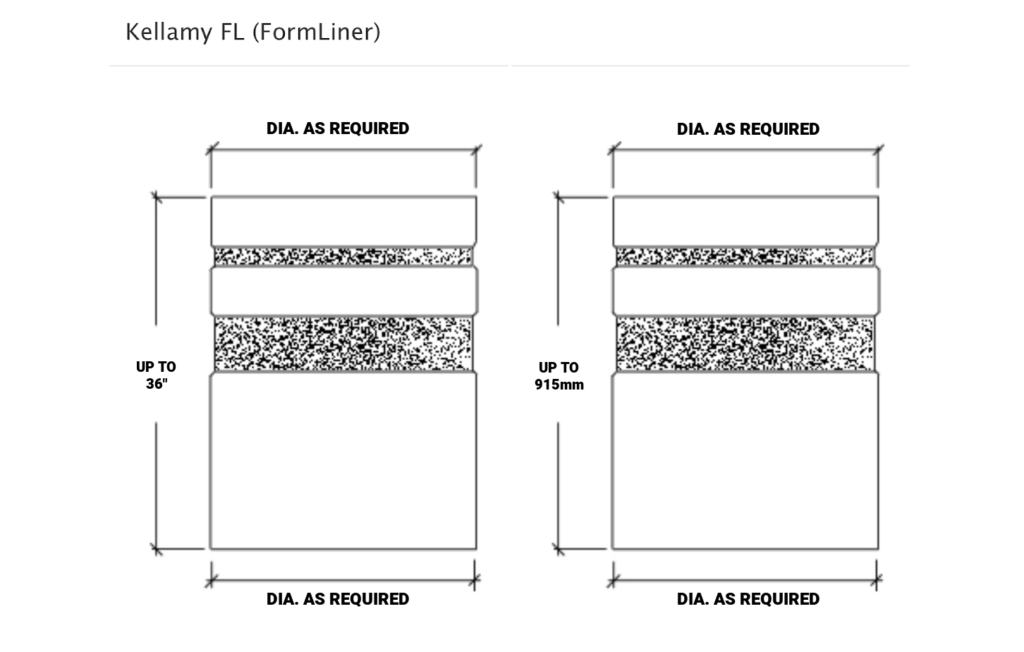

ArtFORMS® Concrete FormLiner

(our latest product innovation – profiled liner for tube forms. For product information, contact the factory).

1 stock contemporary base style (Kellamy FL (FormLiner) is available in any required diameter (small to very large) x any required height up to 36” (915mm).

Are custom ArtFORMS® base styles available?

The Custom Marose base series is available in 4 sizes.

The production of other custom ArtFORMS® Concrete Forms to meet the customer’s custom concrete base & bollard style & size requirements, can be considered on a selective basis.

What are the most popular ArtFORMS® base styles for site lighting poles?

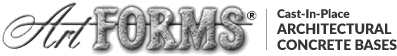

For contemporary style poles up to 50’ (15.2m) high, the Kellamy 610R base at 24” (610mm) Diam. x 36” (915mm) H, or lower (i.e. can be installed at any desired Ht. up to 36” (915mm), complete with Reflective Color Accent Band(s) (this style base can be fitted with 1 or 2 bands). The Kellamy ArtFORMS® Concrete Form fits a 24” (610mm) Diam. standard tube-form used to form the below-grade concrete foundation.

For contemporary style poles up to 35’ (10.7m) high, the Kellamy 610R base & the Newavea 510R-High & Low base, complete with Reflective Color Accent Band (1 band). The Newavea-High base has a 20” (510mm) Diam. head / 18” (460mm) Diam. shaft x 34” (865mm) H, or lower (i.e. can be installed at any desired Ht. up to 34” (865mm). The Low base is 20” Diam. x 12” (305mm) H. The Newavea 510R-High & Low ArtFORMS® Concrete Forms fit an 18” (460mm) Diam. standard tube-form used to form the below-grade concrete foundation.

The Newavea-High base is ideal for parking lots for lighting poles up to 35’ (10.7m) H where a raised base is required to protect the pole from vehicle contact. The High base is an attractive architectural site feature. When installed in all settings, including grassed & planted areas, it provides visual continuity across the entire site including the parking lot. The High base also has the important advantage of the plain shaft section easily accomodating grassed slopes & other variations in site grade lines.

For traditional & contemporary style lighting poles, all heights, the Classica series of enduring, elegant low-profile bases is available in 4 sizes – 24” (610mm) Diam. (top of conc.) x 8” (200mm) H; 18” (460mm) Diam. x 6” (150mm) H, 12” (305mm) Diam. x 4” (100mm) H, 10” (250mm) Diam. x 5 (125mm) H”.

The Classica base provides an easy low-cost way for Specifiers / Owners to ‘dress up’ a low-cost, ‘low-end’ lighting pole / fixture & achieve a ‘high-end’ look.

For traditional style lighting poles, all heights, requiring a raised concrete base e.g. parking lots, the Custom Marose series of enduring, elegant raised bases is available in 4 sizes-in Diams.(top of conc.) of 24”(610mm) , 18” (460mm), 12” (305mm) & 10” (250mm). All at up to 30” (760mm) H (max).

The Custom Marose raised base makes it feasible for Specifiers / Owners to enhance the appearance of their parking lots with a quality traditional lighting pole. The elegant Marose base overcomes the past deterrent to parking lot lighting with elegant vintage lamp posts due to the visual incompatibility between distinctive lamp posts & crude, unsightly, raised concrete tube-formed bases.

The traditional Classica & Marose series bases are not designed for fitting out with optional Reflective Color Accent Bands.

(See Gallery + CAD Drawings & Specs)

Forms material is environmentally friendly. It can be recycled & made into other products. It is inert & can be conveniently used as clean site fill on jobsites, where applicable. It is biodegradable in commercial landfill sites.

Are ArtFORMS® bases suitable for other, non-site lighting concrete support base applications?

ArtFORMS® bases are highly versatile. In addition to site lighting installations, affordable, attractive, quality ArtFORMS® bases are ideal for….. floodlight bases, lighting bollard bases, protective bollard, flagpole bases, column bases, sign post bases, gazebo/pavilion/pergola/trellis post bases, fence/gate post bases, deck post bases, porch post bases, driveway lamp post bases, numerous other concrete base applications.

Are ArtFORMS® Concrete Forms a proven product?

ArtFORMS® Concrete Forms were conceived & developed over several years & successfully introduced to the North American market in 1992. ArtFORMS® is a registered trademark. ArtFORMS® base styles are registered designs.

Thousands of completed ArtFORMS® cast-in-place architectural concrete base installations to date have enhanced the appearance of new & upgrade building projects all across the United States, Canada & beyond at a fast-growing rate.

ArtFORMS® bases for site lighting poles have been adopted as ‘design standards’ by numerous national corporations, well-known institutions, major property developers / builders & a host of other customers, large & small.

What are ArtFORMS® Concrete Forms made of?

ArtFORMS® Concrete Forms are a proprietary product. They are made of strong, lightweight, easy-to-handle, recyclable, biodegradable material.

ArtFORMS® units are produced in identical half-round sections with a smooth outside surface & an architecturally-featured inside surface. The two halves are interlocked face-to-face & steel-banded securely together at the factory into a single tubular unit.

The inside surface of each ArtFORM unit is treated at the factory with a special release agent. This enables the Contractor on the jobsite to strip (‘release’) the ArtFORMS® forming material freely away from the finished concrete base after the concrete has sufficiently strengthened.

Are ArtFORMS® Concrete Forms re-usable?

ArtFORMS® are a convenient, cost-effective, recyclable & biodegradable product. Due to the composition of the forming material & the necessary design of the product, irreparable damage is unavoidable when the material is stripped away from the finished concrete base.

Accordingly, ArtFORMS® are not re-usable. However, ArtFORMS® are suitable for recycling into other products. Also, biodegradable in commercial landfills.

Who are the key specifiers of ArtFORMS® bases?

Owners, Developers, Builders, Architects, Electrical Engineers, Structural Engineers, Landscape Architects & Lighting Designers are the key specifiers of ArtFORMS® bases.

How are ArtFORMS® bases installed?

ArtFORMS® Concrete Forms are used to produce the visible, above-grade concrete base section only of the combined above-grade base / below-grade foundation installation. In a typical ArtFORMS® base installation, standard tube forms are used to provide the required below-grade cast-in-place concrete foundation. ArtFORMS® units are designed to fit snugly, with no bracing required, on top of the appropriately-sized tube form which has been placed in an augured or dug hole in the ground, followed by placement within the tube form of the specified reinforcing steel (“rebar cage”) & electrical wiring conduits.

In a typical ArtFORMS® base pour, the specified ready-mix concrete is poured through the open top of the ArtFORMS® unit, filling from the bottom of the tube form to the top of the ArtFORMS® unit. The concrete should be mechanically vibrated by the Contractor with a small (“pencil”) vibrator, per accepted practice.

For best surface finish results, it is strongly recommended that the Contractor vigorously hand tap e.g. with a 2’+/- (610mm) length of wooden ‘2 x 4’, the outside surface of the ArtFORMS® unit during the concrete pour. Hand-tapping at 4”-6” (100mm-150mm) intervals, top to bottom & 360 degrees around the ArtFORMS® unit, produces a smooth attractive concrete surface finish on the base.

Once the concrete has been poured, the Contractor places the anchor bolt assembly for the lighting pole (or other) into the wet concrete at the top of the ArtFORMS® unit.

Do ArtFORMS® bases require a special concrete mix design?

ArtFORMS® bases do not require any special concrete mix design to produce excellent finished concrete quality & appearance. Regular 3000 psi mix with 3″ slump is standard.

How are ArtFORMS® bases stripped?

For easy release of the ArtFORMS® Concrete Forms material from the concrete, ArtFORMS® bases should normally be stripped within 24 hours after the base is poured.

To strip the base, the contractor cuts away the securing steel bands & pries the 2 ArtFORMS® halves apart at the 2 vertical seams with a long-handled ice scraper, square-nose shovel, or other flat- bladed hand-tool. The material will generally release from the concrete with the 2 halves for the most part intact, but irreparably damaged.

It is recommended that the stripped ArtFORMS® halves be used to provide physical protection for the finished bases where the bases may be vulnerable to damage by construction equipment on the jobsite. The 2 halves can be quickly duct-taped or tie-wired back in place around the base & left in place until it is safe to remove the protection.

(See Installation)

What are optional Reflective Color Accent Bands?

Reflective Color Accent Bands are a popular option. Available in a wide selection of colors, they are an attractive architectural feature in all settings. The high-visibility (daytime/nightime) reflective bands are a traffic safety feature when fitted on ArtFORMS® concrete bases for site lighting poles in & around parking lots.

The Bands are made of high-quality, durable, outdoor colored tape adhered to non-rusting aluminum strips, sized to fit snugly into horizontal recesses formed into the finished ArtFORMS® base.

The Bands are manually fitted (quick ‘n easy) by the installing Contractor anytime after the ArtFORMS® material is stripped away from the concrete. The Bands are self-locking for a secure, vandal-resistant fit.

How can prices be obtained for ArtFORMS® Concrete Forms & a purchase made?

Contact the factory.

For most regions, ArtFORMS® prices are quoted, sold & shipped factory-direct. In selected regions, ArtFORMS® prices are quoted & orders are placed through local manufacturers sales representative offices.

(See Quote Request)

How are ArtFORMS® Concrete Forms shipped?

ArtFORMS® are shipped factory-direct to the customer’s jobsite (other destination), North America-wide, by expeditious ground transportation.

Guidelines for ArtFORMS® base Installation & Stripping are included with the product.

Stock ArtFORMS® orders are shipped to arrive at the jobsite (or other destination) typically in 2 to 7 business days, depending on the shipping distance.

Custom ArtFORMS® orders are shipped to arrive at the jobsite (or other destination) typically in 14 to 21 business days after the order is placed.